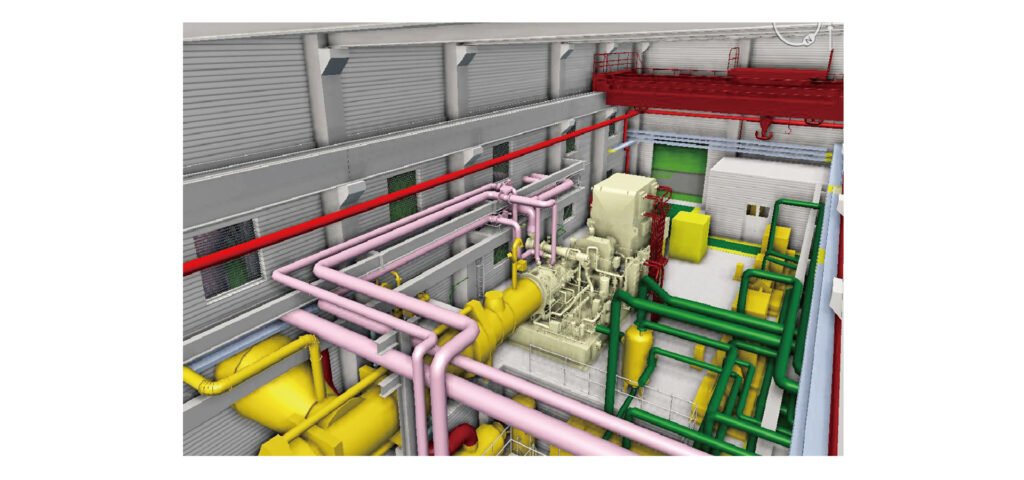

In the modern power generation industry, the steam turbine island serves as the heart of thermal power plants. A steam turbine island integrates turbines, generators, condensers, feedwater systems, and auxiliary equipment into one coordinated unit. Its performance directly determines the efficiency, reliability, and overall competitiveness of a power plant. With growing pressure to reduce emissions and enhance output, steam turbine island performance optimization has become a central focus for plant operators and investors worldwide.

The Importance of Steam Turbine Islands

The steam turbine island is responsible for converting thermal energy into mechanical and electrical energy. Even small improvements in turbine efficiency can lead to significant gains in overall plant output. For example, a 1% improvement in turbine efficiency can translate into millions of kilowatt-hours of additional electricity annually. Optimized steam turbine islands not only improve profitability but also reduce the specific fuel consumption, lowering operational costs and environmental impact.

Steam Turbine Island Performance Optimization

Performance optimization involves both hardware and software approaches. On the hardware side, upgrading blades, seals, and heat exchangers can improve steam flow and reduce energy losses. On the software side, advanced monitoring and digital twin technologies help operators identify inefficiencies in real time. By adopting predictive analytics and automated controls, plants can maintain peak efficiency under varying load conditions. Companies that specialize in steam turbine island performance optimization offer tailored solutions that extend equipment lifespan and deliver measurable performance gains.

Role of Steam Turbine Suppliers

Reliable steam turbine suppliers are essential partners in ensuring the long-term success of turbine islands. Leading suppliers provide not only high-quality turbines but also integrated engineering services, including installation, commissioning, and after-sales support. The choice of supplier significantly impacts plant performance, as well-designed turbines ensure better load adaptability, higher efficiency, and longer operational life. Today, suppliers are also focusing on hybrid solutions that integrate steam turbines with renewable energy systems, making them central to the future of sustainable power generation.

Steam Turbine System Maintenance

No turbine island can sustain long-term performance without effective steam turbine system maintenance. Preventive maintenance programs include regular inspections, vibration monitoring, lubrication checks, and thermal performance assessments. Modern digital tools make it possible to predict component wear and prevent costly failures before they occur. Well-maintained turbine islands operate at higher efficiency, with less unplanned downtime, ensuring stable and reliable electricity generation. Investing in systematic maintenance not only reduces risks but also lowers lifecycle costs for power plants.

Runh: A Trusted EPC Partner

Among global engineering companies, Runh Power has built a strong reputation for delivering reliable EPC (Engineering, Procurement, and Construction) solutions for power plants. With successful projects in Asia, Africa, Europe, and South America, Runh specializes in building highly efficient boiler and steam turbine islands. The company offers end-to-end solutions, from design and manufacturing to installation and long-term maintenance. By leveraging deep expertise and global experience, Runh helps clients achieve optimal power plant efficiency, reduced emissions, and improved return on investment. For plant owners seeking a partner in turbine technology and EPC services, Runh stands out as a trusted name.

Environmental and Economic Benefits

Optimized steam turbine islands not only enhance performance but also provide environmental and economic advantages. Higher efficiency translates into lower fuel consumption and reduced greenhouse gas emissions. Economically, power plants benefit from improved capacity utilization, greater reliability, and lower operational costs. In regions where renewable integration is advancing, steam turbine islands play an important role in stabilizing the grid and ensuring energy security.

Future Trends in Steam Turbine Islands

The future of steam turbine technology lies in digitalization, hybridization, and sustainability. Digital control systems, AI-based monitoring, and data-driven predictive maintenance will dominate the next generation of turbine operations. Hybrid systems combining turbines with solar, wind, or battery storage will become increasingly common, offering flexible power solutions. As countries push towards carbon neutrality, steam turbine islands will remain indispensable in balancing energy supply and demand.

Conclusion

Steam turbine islands remain at the core of power plant performance, offering unmatched efficiency and reliability. With advancements in steam turbine island performance optimization, the support of leading steam turbine suppliers, and the implementation of effective steam turbine system maintenance, power plants can achieve long-term competitiveness. Companies like Runh are helping shape the future of efficient, sustainable, and profitable energy systems worldwide. By focusing on continuous improvement and innovation, steam turbine islands will continue to play a key role in the global energy transition.

Instant

Quote

Instant

Quote Email

Us

Email

Us