In modern power plants, the steam turbine island plays a central role in energy conversion and overall plant efficiency. Optimizing the performance of these systems is critical to ensuring maximum output, minimal downtime, and long-term operational reliability.

As the demand for cleaner and more efficient power grows, plant operators are increasingly investing in steam turbine island performance optimization strategies to enhance efficiency, reduce fuel consumption, and extend the lifespan of key equipment.

Strategies for Performance Optimization

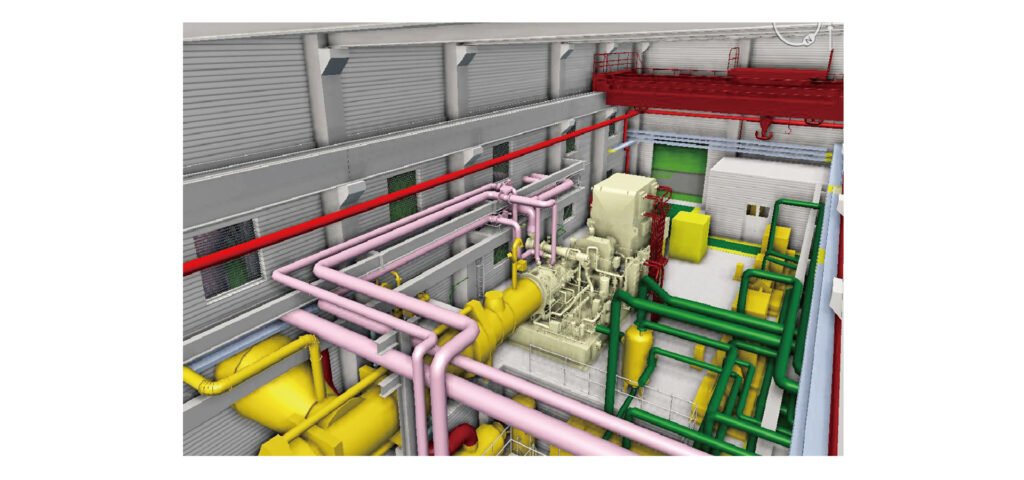

Optimizing a steam turbine island involves multiple approaches, including advanced monitoring, control system upgrades, and mechanical maintenance. By analyzing turbine performance data in real time, operators can identify inefficiencies, anticipate maintenance needs, and adjust operating parameters to maximize output.

A critical part of this process is integrating modern technologies such as predictive maintenance tools and automated controls. These innovations not only improve energy efficiency but also reduce operational costs, making the plant more competitive and environmentally friendly.

The Role of Retrofits

Many plants achieve significant efficiency gains through steam turbine island retrofits. Retrofitting allows operators to modernize existing turbines without the need for complete replacement, which can be costly and time-consuming. Retrofits may include upgrades to blades, seals, and control systems, all designed to enhance performance and reduce emissions.

These retrofits are particularly valuable for older plants where legacy equipment may limit efficiency. By implementing targeted retrofits, operators can achieve higher output, lower fuel consumption, and improved reliability, extending the operational lifespan of the steam turbine island.

Choosing the Right Manufacturer

Selecting the right steam turbine manufacturers is crucial for achieving successful outcomes. Runh Company, as a leading manufacturer, specializes in designing, producing, and supplying high-performance steam turbines that integrate seamlessly with modern power plants.

Runh turbines are engineered for durability, efficiency, and adaptability. The company’s solutions support steam turbine island performance optimization through advanced design, high-quality materials, and precise engineering. Their comprehensive support includes maintenance guidance, technical training, and retrofit services, ensuring that plants operate at peak performance throughout their lifecycle.

Environmental and Economic Benefits

Optimizing steam turbine islands offers both environmental and economic advantages. Enhanced efficiency reduces fuel usage, leading to lower emissions and operational costs. Well-maintained and retrofitted turbines minimize downtime, improve energy output, and support reliable power delivery to consumers.

In addition, working with experienced steam turbine manufacturers like Runh ensures that retrofits and performance optimization measures are implemented to industry best practices, maximizing both return on investment and environmental compliance.

Case Studies and Success Stories

Several plants have successfully improved performance through retrofits and optimization programs. For example, a mid-sized thermal power plant upgraded its steam turbine island components using Runh technology. As a result, the plant achieved a 12% increase in efficiency, reduced fuel consumption by 8%, and maintained consistent power delivery even during peak demand periods.

These examples demonstrate that combining modern engineering, targeted steam turbine island retrofits, and expert manufacturer support results in measurable performance improvements and long-term operational benefits.

Future Outlook

The future of steam turbine islands involves integrating digitalization, predictive analytics, and hybrid energy systems. These innovations will allow plants to continuously monitor performance, optimize efficiency, and reduce environmental impact. Manufacturers like Runh are at the forefront of these developments, offering turbines and retrofits designed to meet the evolving needs of modern power plants.

Conclusion

Optimizing the steam turbine island is essential for modern power plants aiming to improve efficiency, reduce costs, and support sustainable energy generation. Through steam turbine island performance optimization, targeted steam turbine island retrofits, and collaboration with leading steam turbine manufacturers like Runh, plants can achieve long-term operational excellence and environmental compliance.

Instant

Quote

Instant

Quote Email

Us

Email

Us